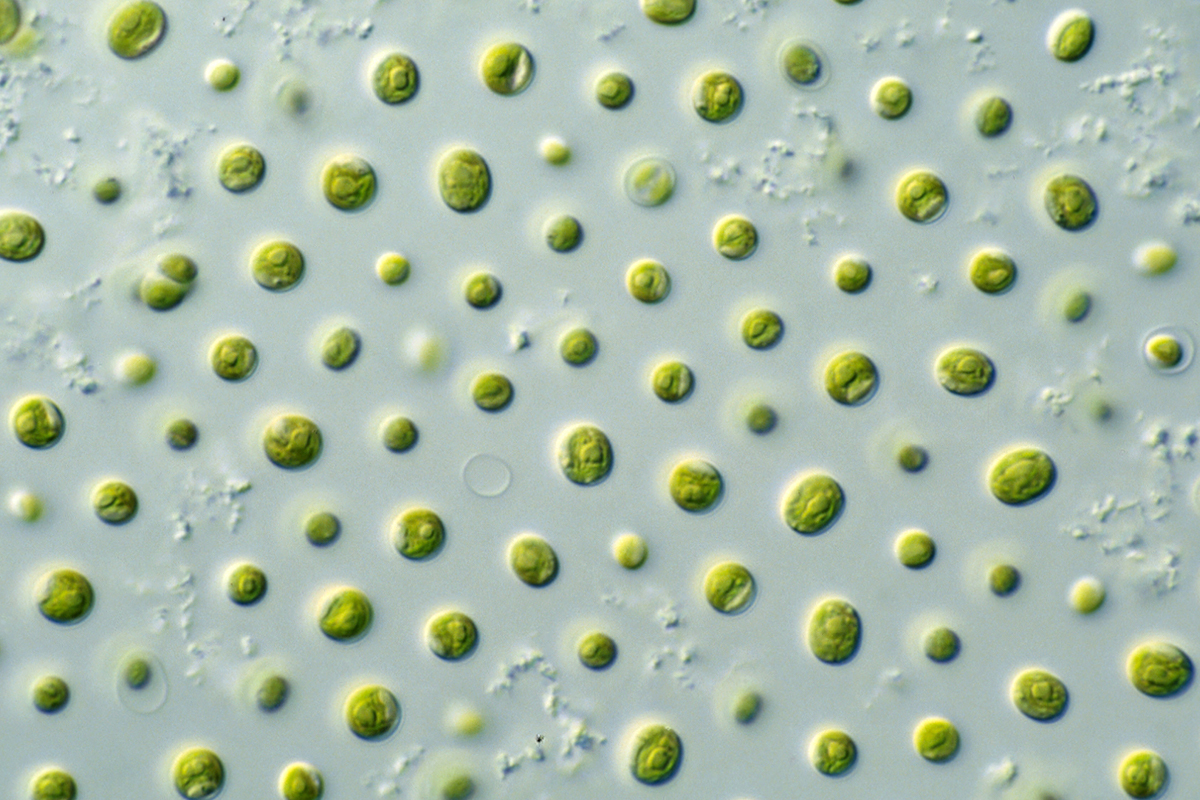

NRI is part of a recently started, two-year project to develop a new technology to manufacture protein with an improved flavour profile, from microalgae. The incorporation of algae into human food systems has gained increased attention in recent years, with significant interest in microalgae as an alternative protein source.

The project is part of the ‘novel low-emission food production systems competition’ funded by Innovate UK and the Biotechnology and Biological Sciences Research Council (BBSRC). Innovate UK and BBSRC are supporting innovative projects that will revolutionise diets and sustainability by developing environmentally friendly means of food production. The project will be delivered in partnership with Imperial College London (ICL) and London-based biotechnology start-up Arborea Ltd.

As the global population and incomes rise, people will increasingly consume more resource-intensive, animal protein-based foods. By 2050, the world will need to produce twice as much protein as it does today to feed its population. This would require an extra 25,000 km2 grazing land for traditional animal protein production. Plant-based protein like soy is currently widely used in the UK but has sustainability issues associated with its importation. It racks up considerable food miles on its way from source countries, Brazil and China. A recent study shows that food miles are responsible for 3 billion tonnes of carbon dioxide equivalent emissions, indicating that transport is responsible for roughly 19% of all food system emissions. There is therefore a critical need to identify environmentally friendly, home-grown alternative protein sources that require less natural resources for production.

The potential of microalgae as an alternative protein source is limited by conventional protein extraction methods for microalgae which are expensive, quite unsustainable, inefficient and can create ‘off-flavours’ caused by the presence of undesirable compounds.

To tackle this challenge, NRI scientists will identify the critical compounds leading to the off flavour in microalgae. They will also explore how the flavour relates to and changes with algae growth conditions and protein extraction methods. This work will be led by NRI’s alternative protein expert Dr Parag Acharya and Dr Yixing Sui, an algae biotechnologist at the University of Greenwich’s School of Science. ICL will develop innovative, cost-effective and environmentally friendly methods to produce algal protein extract. Arborea has patented bioreactor technology to harvest microalgae cost-effectively. They will bring this expertise in the industrial growth and harvesting of microalgae to the project.

NRI has built the capability to develop alternative protein-based food products and process technologies through its partnership in the Medway Food Innovation Centre (MFIC). This includes an advanced analytical platform for measuring flavour and texture of food products which are some of the critical quality attributes driving consumer acceptance. The ultra-modern facilities at MFIC will help Parag and his team to develop novel technology for targeted removal or masking of off-flavours during the process of upscaling of algal protein production. This will help improve consumer acceptance of food products derived from micronutrient rich and sustainable protein sources like microalgae.

Dr Acharya said: ‘I'm excited to win this collaborative project which will not only facilitate low carbon food production but also help to address the nutrition gap of plant-based food.’ This nutrition gap arises from concerns that plant-based diets are deficient in certain key micronutrients such as Vitamin B12 compared to animal product-based diets.’

The Medway Food Innovation Centre at the University of Greenwich offers state-of-the-art facilities, some of which are unique to the UK, to transform the UK food and drink sector. Led by Dr Acharya, it provides the industry with cutting-edge technical support and research and development capabilities. The Centre has leading expertise in food processing, plant and algal protein-based product development, flavour and texture analysis, food safety, packaging and fresh produce storage.

For more information: