After harvesting, fresh cassava roots must be consumed or processed within 72 hours, or they become unsuitable for human consumption. For this reason, the roots are usually processed into dried products including flour and gari – a granular, fermented, roasted product – that can be used later as the basis for various dishes. Cassava processing involves numerous stages including peeling, grating, pressing, pulverising, drying, and milling, which in many places, are carried out by hand.

In order to make these tasks more efficient and less laborious, some cassava processing centres in Africa are looking to mechanise their operations. However, many of these are small or medium-sized enterprises (SMEs) whose expansion is constrained by a lack of appropriate, affordable, and efficient processing equipment. Here we highlight two projects that are harnessing solar power and the latest advances in agricultural engineering design to develop efficient cassava processing technologies suitable for village enterprises, which can reduce postharvest losses and food insecurity, and improve livelihoods.

Solar-powered pre-heater

Firewood is often associated with deforestation, exposure to pollutants, and CO2 emissions, though it is still widely used as a heat source in many postharvest operations in developing countries, particularly in drying. Many projects have aimed to develop postharvest technologies that use more sustainable heat sources such as solar energy, biogas, or bioethanol, but in low-income countries, the adoption of those technologies by SMEs has been limited. To reduce fuel consumption, NRI’s Dr Marcelo Precoppe, a Crop Postharvest Technologist, led a project funded by GCRF AgriFood Africa Innovation to develop a solar-powered pre-heater for a flatbed dryer used for cassava processing. By pre-heating the drying air, this reduces the amount of energy needed to reach the target temperature of the dryer.

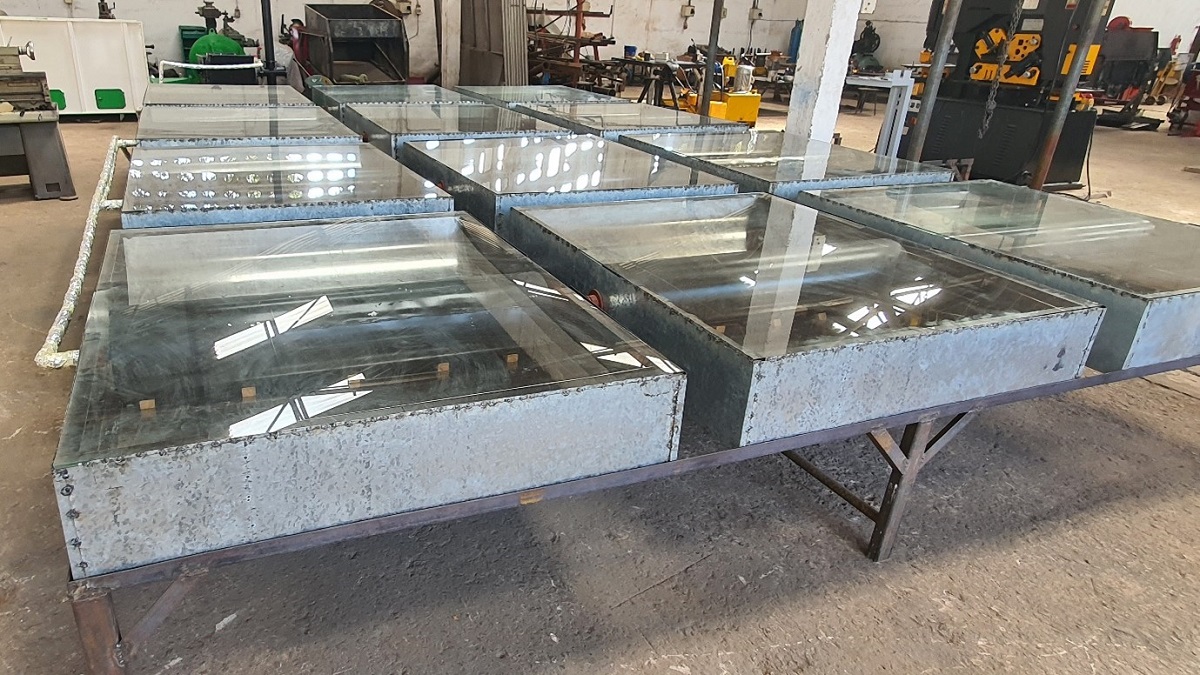

The innovative aspect of this design is that it uses solar power to heat water, which stores more energy than air. The heater consists of a series of 12 black tubes containing water, which are heated by the sun. Surrounding each black tube is a parabolic reflector made of sheet metal which helps to concentrate the sun’s rays. Each black tube and reflector is housed in a glass-covered insulated box to increase the heat of the water. Water heaters typically store hot water in a separate insulated tank, but in this project, Dr Precoppe designed an integrated system which acts as both storage tank and solar collector. The heat is then passed through an ordinary car radiator, placed at the heat exchanger air inlet, which transfers the heat from the solar collector to the air used for drying.

The heater is sturdy, durable, and was built and tested with project partners in Tanzania, Intermech Engineering, using locally available materials to reduce costs. It can reduce by up to 80% the fuel consumption used during a drying operation. Because of its low costs, the payback period from investing in its construction is short, and the team hopes this technology will proliferate throughout sub-Saharan Africa.

Solar-powered multipurpose hammermill

During processing, cassava roots must be reduced to a manageable size. A ‘hammermill’ is one of the most-used pieces of equipment to do this and works by the repeated blows of little hammers. A project led by NRI’s Dr Aditya Parmar, a Crop Postharvest Scientist, has developed a solar-powered multipurpose hammermill that can be used to grate the cassava root, pulverise it into mash and mill the dried cassava grits. It is a versatile tool to replace the two or more separate machines currently used for these processes – which could be transformative in terms of costs and benefits to many people in rural Ghana and potentially in other regions.

Hammermills are usually used designed for a single product and a single particle size. In this project, Dr Marcelo Precoppe used specialist particle simulation software – ESSS Rocky – to design a hammermill that can be used for several different products and different particle sizes. To grate the cassava and to pulverise the mash, the hammers rotate in one direction. To mill the dried grits, the hammers rotate in another direction. The hammers have a special design – with one sharp side and one blunt side. The direction of rotation for milling activates the fan; this is necessary to move the product through the machine, because when milling, the product is too small and light and does not move by gravity.

Instead of using diesel, this machine runs purely on solar energy – harnessing the daily average of six to seven hours of sunshine in West Africa, thus reducing production of greenhouse gases. Although the machine cannot store energy and will only power-up when the sun is shining, most processing traditionally takes place during daylight hours. It was carefully designed to run using direct current (DC) motors, which are much less powerful than the motors usually employed on hammermills. Unlike in typical photovoltaic systems with batteries, charge controllers and other additional electronics, the project team reduced costs further by adding a ‘direct coupling system’ by connecting the photovoltaic panels directly to the DC motors. Recent advancements in technology mean that the cost of solar panels has reduced the overall cost of photovoltaic systems by 90%. The absence of any maintenance or fuel costs will quickly offset the initial cost of buying this machine.

A key objective was to strengthen local capacity, and the team worked closely with two Ghanaian partners, the Food Research Institute, and First Product Enterprise Ltd., who manufactured the hammermill. It is currently being used at a cassava processing centre in Accra. The next steps include scaling up production, collaborating with the local manufacturer, who will play a vital role in disseminating knowledge and creating new jobs in Ghana. If the machine is a success, NRI hopes to facilitate its production more widely across cassava-growing regions in Africa.

This activity was part of a project funded by Agri-Tech Catalyst (Innovate UK).